Views: 0 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

Ever noticed how conveyor systems in factories keep running smoothly—without slipping backward even once? That’s the magic of backstop clutches. They might not be flashy, but these small components are the backbone of countless industrial systems, ensuring safety, efficiency, and precision in motion control.

In this article, we’ll explore what makes backstop clutches so essential, and more importantly, which manufacturers around the world are leading the game.

A backstop clutch, also known as a holdback or anti-reverse clutch, allows rotation in one direction while preventing motion in the opposite direction. Picture a bicycle wheel: you can pedal forward freely, but try going backward, and the gear locks. That’s essentially how a backstop clutch functions—on a more industrial scale.

There are several types:

Sprag clutches

Roller ramp clutches

Cage-type clutches

Cam clutches

Each type is engineered to meet specific torque, speed, and space requirements.

You’ll find these little guardians in:

Conveyor systems

Elevators and escalators

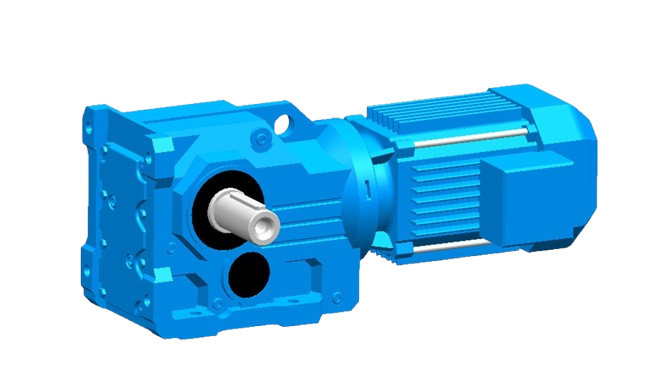

Gearboxes and reducers

Mining and cement machinery

Automotive transmissions

Their job? Prevent reverse rotation that could damage machinery or cause accidents.

Not all clutches are created equal. The manufacturer’s expertise determines how reliable, durable, and efficient your clutch will be.

High-performance backstop clutches rely on precision machining, heat-treated materials, and corrosion-resistant finishes to survive high torque and continuous operation.

Top manufacturers offer custom-built clutches for unique industrial setups—because one size rarely fits all.

A clutch failure in the middle of production can be costly. That’s why manufacturers who provide responsive technical support and fast spare parts delivery stand out.

Tsubaki is synonymous with excellence in motion control. Their BS Series backstop clutches are widely used in conveyor systems and heavy machinery. With over a century of innovation, Tsubaki remains a trusted name across industries.

RINGSPANN specializes in high-precision power transmission components. Their backstop clutches feature compact design, low backlash, and long life expectancy, making them ideal for demanding mining and bulk handling operations.

Based in Jiangsu, China, Suma Precision is rapidly earning global attention for its one-way clutches, needle roller bearings, and backstop clutches. Known for cost-effective yet reliable designs, Suma’s products are widely used in metallurgy, mining, and automation industries.

As part of the Schaeffler family, Stieber delivers German engineering excellence. Their products are known for high torque density and energy-efficient design, suitable for conveyors, elevators, and wind turbines.

Marland specializes in torque-limiting and backstop clutches designed for tough applications like conveyors and bucket elevators. Their designs feature oil-immersed lubrication systems for extended life.

Renold’s backstop clutches reflect the company’s long-standing tradition of British precision engineering. They serve industries such as cement, quarrying, and energy with durable and easy-to-maintain units.

GMN produces high-speed precision clutches known for their low noise and long service intervals. They’re a preferred choice for robotics, automation, and aerospace applications.

Rexnord’s portfolio covers everything from chain drives to backstop clutches, designed for maximum uptime. Their global service network ensures quick support and reliable parts availability.

This partnership merges Stieber’s clutch innovation with Koyo’s bearing expertise. The result? Compact and efficient backstop solutions suitable for electric motors, conveyors, and precision drives.

Formsprag, under the Altra Motion umbrella, has set the benchmark for reliable overrunning and backstopping solutions. Their products are trusted in aerospace, mining, and material handling sectors worldwide.

China’s precision engineering market is booming. Companies like Suma, C&U, and Harbin Bearing are expanding globally by offering customized clutches at competitive prices. Similarly, India is stepping up with firms that combine affordability with ISO-certified quality.

Local manufacturers are now investing in CNC machining, heat treatment, and quality testing equipment, allowing them to rival traditional European brands in both accuracy and lifespan.

In conveyor belts, a single reverse rotation could cause tons of materials to spill. Backstop clutches prevent that from happening.

These industries depend on rugged clutches that can handle shock loads and harsh conditions—a specialty of companies like Marland and RINGSPANN.

Backstop mechanisms are crucial in EV transmissions, enabling smooth deceleration and efficient torque transfer.

Modern turbines rely on one-way and backstop clutches to prevent reverse spinning and protect the gearbox under wind fluctuations.

The right clutch should handle both normal and peak loads without failure. Always check torque capacity and operating speed.

Space can be tight in industrial setups—make sure the clutch fits your existing shaft and housing design.

Improper lubrication is the #1 cause of premature clutch wear. Choose sealed or oil-lubricated types based on your environment.

Going cheap can backfire—literally. Lower-cost clutches may lack precision or heat treatment, leading to early failure.

Always verify ISO, CE, or IATF certifications to ensure product consistency and safety.

A great clutch is only as good as the support behind it. Look for suppliers offering technical consultation and spare parts.

Imagine clutches that monitor their own wear and temperature in real-time. Smart sensors are making that a reality.

Expect to see more hybrid ceramics, stainless steel alloys, and surface coatings that resist wear and corrosion.

Manufacturers are focusing on lightweight, friction-optimized designs to improve overall energy efficiency in industrial drives.

A backstop clutch might seem like a small component, but it plays a huge role in keeping industries safe and efficient. Whether you’re sourcing from global giants like Tsubaki and RINGSPANN, or rising manufacturers like Suma Precision, always prioritize quality, engineering excellence, and after-sales support.

Because when your entire operation depends on one direction—failure simply isn’t an option.