Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

Backstop clutches might not look like much, but trust me—they’re the quiet heroes inside conveyor systems, bucket elevators, mining equipment, and any machine that absolutely cannot afford reverse rotation. If you’ve been searching for reliable, affordable, and high-performance backstops, China has quickly become one of the most competitive sources in the world.

In this guide, you’ll discover the five most reputable Chinese backstop clutch manufacturers—companies trusted globally for quality, innovation, and value.

A backstop clutch, sometimes called an anti-reverse clutch, is a device that allows rotation in one direction while preventing motion in the opposite direction. If you’ve ever ridden a bicycle with a freewheel, you’re already familiar with the basic idea.

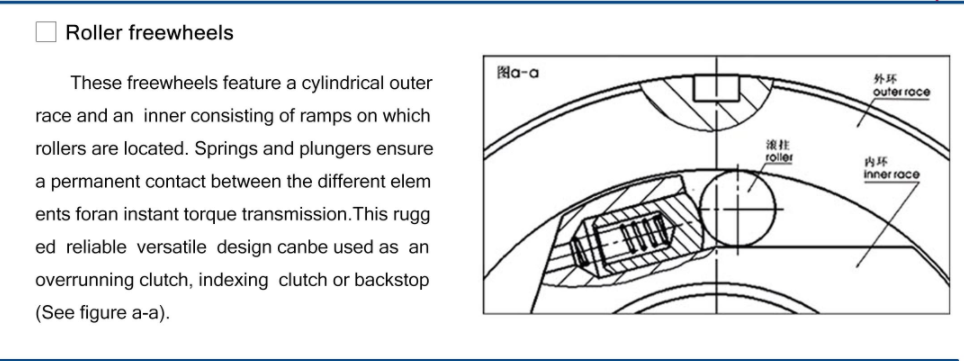

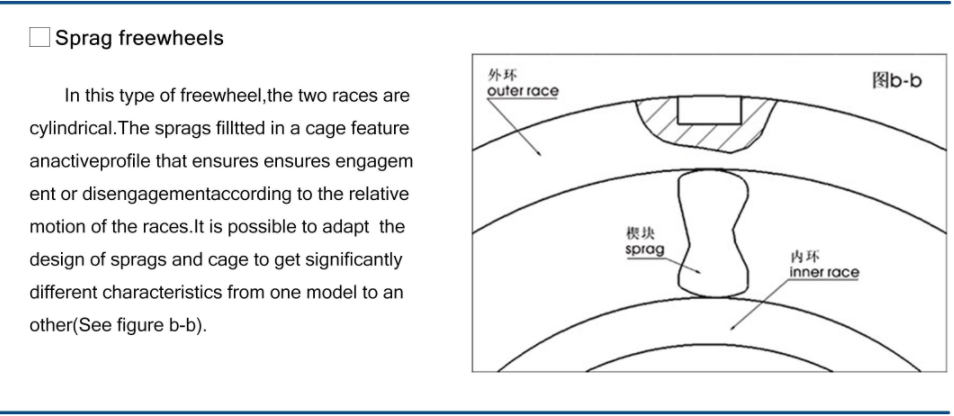

Backstop clutches typically use:

Sprag elements

Rollers or wedges

Cam structures

These engage automatically when reverse rotation is detected—almost like a seatbelt locking when you pull too fast.

Backstop clutches are heavily used in:

Conveyor systems

Mining & bulk material handling

Gear reducers

Bucket elevators

Industrial automation

Packaging equipment

Any system that lifts, conveys, or transfers loads benefits from a reliable backstop.

China’s centralized industrial supply chain enables factories to source steel, heat treatment services, grinding processes, and CNC machining in one region—significantly cutting lead times.

Compared to Europe, the U.S., or Japan, Chinese backstop manufacturers typically provide:

Lower production cost

Shorter delivery times

High customization capability

This makes them ideal partners for OEMs and distributors.

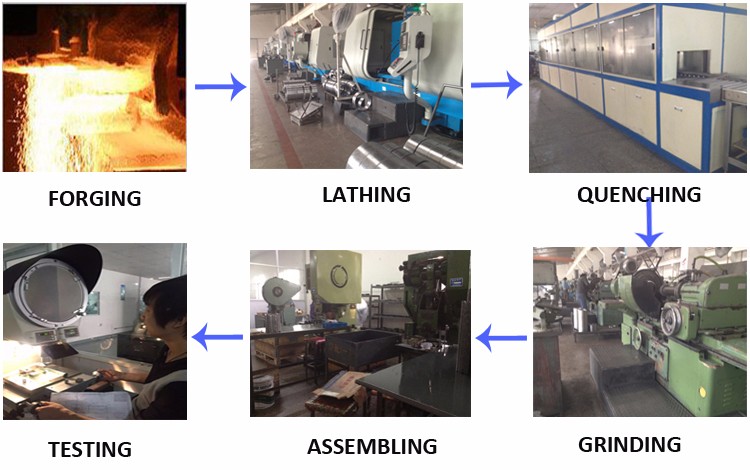

Modern Chinese factories now use:

CNC grinding centers

Automated assembly lines

100% inspection processes

Imported heat-treatment equipment

Quality today is dramatically higher than 10 years ago.

Location: Changzhou, Jiangsu

Specialization: Backstop clutches, one-way bearings, cam clutches, overrunning clutches

Suma has become one of China’s most recognized suppliers of high-precision one-way and backstop clutches. Known for consistent quality and global-friendly service, their products are widely used in conveyors, packaging machines, and mining equipment.

BS-Series Backstop Clutches

RSCI & RSBW Cam Clutches

One-way Needle Roller Clutches

High-torque industrial backstops

Strong R&D and customization capabilities

High heat-treatment consistency using Japanese processes

Exported to Europe, USA, South America, and Southeast Asia

Reliable OEM supplier for industrial brands

Location: Shanghai

Specialization: Cam clutches, transmission solutions

Tsubaki is a global leader with production facilities worldwide. Their China operation maintains the same Japanese engineering standards, offering premium backstop clutches.

BS-F Series

Cam Clutch Backstop Units

High-speed overrunning clutches

World-class precision

Best for high-speed, high-load applications

Strong global support network

Location: Tianjin

Specialization: Industrial power transmission

Renold’s China division manufactures backstop elements with strict UK quality standards.

Backstop clutches for conveyors

Heavy-duty modular units

Industrial torque limiters

Long product lifespan

Excellent engineering support

Trusted in mining, cement, and steel industries

Location: Zhejiang

Specialization: Backstops, one-way clutches, cam clutches

Donglu is known for competitive pricing combined with strong mid-range quality—ideal for smaller equipment manufacturers or cost-focused projects.

RS, RSB, RSE Backstop Series

Overrunning clutches

Cam clutch units

Great price-to-performance ratio

Large-scale production capability

Fast delivery

Location: Shenzhen

Specialization: Custom backstop solutions and one-way bearings

A rising manufacturer offering both standard and custom backstop units.

Custom anti-reverse clutches

Miniature backstop units

Roller-type backstop clutches

Strong design flexibility

Small-batch customization

Modern CNC production environment

Choosing a manufacturer isn’t just about price. Here’s what you should consider:

Higher-torque systems like bucket elevators need heavy-duty backstops with larger sprags or rollers.

Look for:

GCr15 bearing steel

Vacuum or salt-bath heat treatment

Precision grinding tolerances

If your project requires a unique bore size, torque rating, or mounting style, choose a factory with in-house R&D.

A trustworthy manufacturer should offer:

ISO 9001

Material inspection reports

Hardness testing

Torque performance validation

China has become a major force in the global backstop clutch market thanks to its strong manufacturing infrastructure, competitive pricing, and fast innovation. Whether you’re sourcing for conveyors, mining equipment, or packaging machinery, the five companies above represent the best balance of quality, reliability, and cost.

Yes. Many Chinese manufacturers now meet global standards and export worldwide.

Most suppliers, especially Suma and Donglu, support customization.

Mining, packaging, conveyors, cement, material handling, and automation.

Typically 3–10 years depending on load, lubrication, and maintenance.

Yes—several specialize in private-label production for global brands.